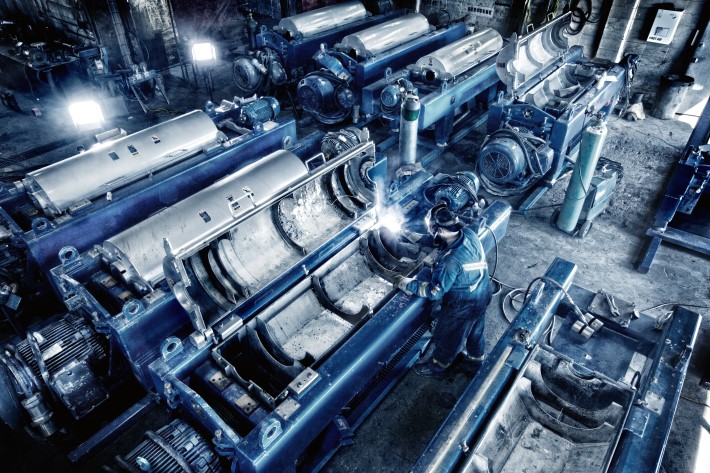

IF IT’S BROKEN WE’LL FIX IT. IF WE DON’T HAVE THE PART, WE’LL MAKE IT.

Right from the very start, Sentrimax made the crucial decision to have the complete capabilities to design and manufacture to OEM specifications virtually any component that makes up a centrifuge. With the facilities and proficiencies of our repair shops, and the skills and experience of our machinists, millwrights and welders, we have yet to encounter a centrifuge part that we cannot build, reverse engineer or redesign to match or, in most cases, exceed the spec of the original. And this has led to one of the largest on-site parts inventories in our industry and gives us immediate parts access when repairing machines for almost any manufacturer including Alfa Laval, Andritz, Tomoe, Sharples, Tecumseh, Hutchison-Hayes, Flottweg and Westfalia. With all the resources we have on hand, Sentrimax provides new or completely refurbished centrifuges for any industrial or commercial application that our customers demand.

DECANTER CENTRIFUGES

Sentrimax can provide new build or completely refurbished centrifuges for any municipal, industrial or commercial process. We will consult with our customer and make precise recommendations as to the most appropriate unit to meet their present and future requirements. Our refurbished centrifuges are rebuilt to OEM specifications and come with a 1-year/18 month warranty.

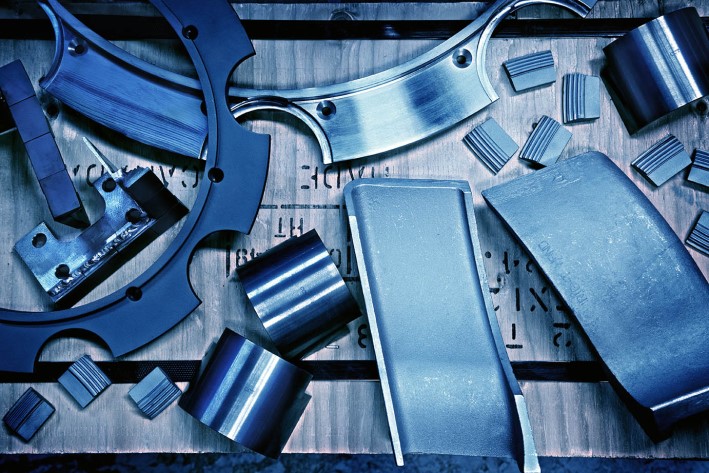

PARTS

Sentrimax maintains a high value inventory of centrifuge parts such as feed zone ports, accelerators, spline shafts, and much more at our facilities. We have made it a priority to be fully capable of designing and manufacturing all decanter centrifuge parts to precise OEM specifications. For components that are outside the capabilities of our manufacturing expertise we have aligned ourselves with the top manufacturers in their respective fields, such as bearings (SKF and FAG) and a European centrifugal casting company for centrifuge bowl and bowl extensions that provides the same quality as the OEM’s. These components are to OEM specifications but are at a fraction of the OEM cost. In addition, with our CAD capabilities, we can design and manufacture one-off or specialized parts and components that our customers request.

WEAR COMPONENTS

Wear components are critical parts of every centrifuge that continually protect key elements from damage caused by abrasive sludge. Sentrimax maintains abundant supplies of tiles, liners, wear rings, plows, saddles, shells, feed zone nozzles and other critical wear components for our customer's convenience and immediate requirements. SCI has aligned itself with a North American carbide manufacturer to build carbide wear components to Sentrimax’s specifications. Sentrimax has the ability to improve the design of wear components based on the wear patterns observed during the repair process of our customer’s centrifuges. With these design and custom manufacturing capabilities we can improve the run time of the customer’s centrifuge(s). Our carbide manufacturer is also ISO 9001:2008 certified and all carbide quality is guaranteed. This is ensured through quality assured testing for abrasion resistance using the ASTM G-65 abrasion test to guarantee minimum OEM standards are met.

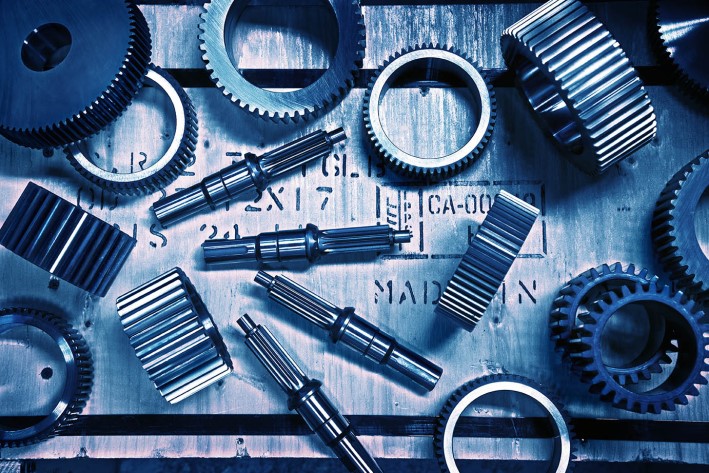

GEARBOXES & GEARBOX COMPONENTS

Gearboxes are the backbone of a decanter centrifuge. Sentrimax has long specialized in refurbishing used gearboxes for resale, as well as manufacturing the specialized components that make up a decanter centrifuge gearbox. Two and three stage planetary and cyclo gearboxes are just a few examples that we carry parts for.

USED PARTS

As Sentrimax completes repairs and rebuilds to both municipal and industrial centrifuges, we invariably acccumulate a significant quantity of used parts. Our used parts are refurbished back to OEM specifications and quality is backed with a 1-year warranty.

FRAME MANUFACTURING & REPAIRS

Centrifuge frames can take a lot of abuse, but frames built by Sentrimax can withstand the punishment. Our manufacturing processes ensure that every frame we build or repair is of the highest and strongest quality in the industry, and we utilize Laser alignment to ensure bearing pillow block mounting location pins are in alignment in all three directions to within OEM specifications.

BEARINGS AND SEALS

Sentrimax utilizes only tier #1 bearing manufacturers SKF, FAG and NSK for our centrifuge rebuilding and refurbishing operations. We also utilize OEM or equivalent seals with the proper size and material composition for the application and process fluids they will be exposed to (i.e. Buna, Viton, Harbor, etc.).

MOTORS AND MOTOR REPAIRS

Sentrimax keeps a ready inventory of centrifuge motors in stock at all times, and our turnaround time on motor repairs recognizes that operations immediately come to a halt if the motor is down.